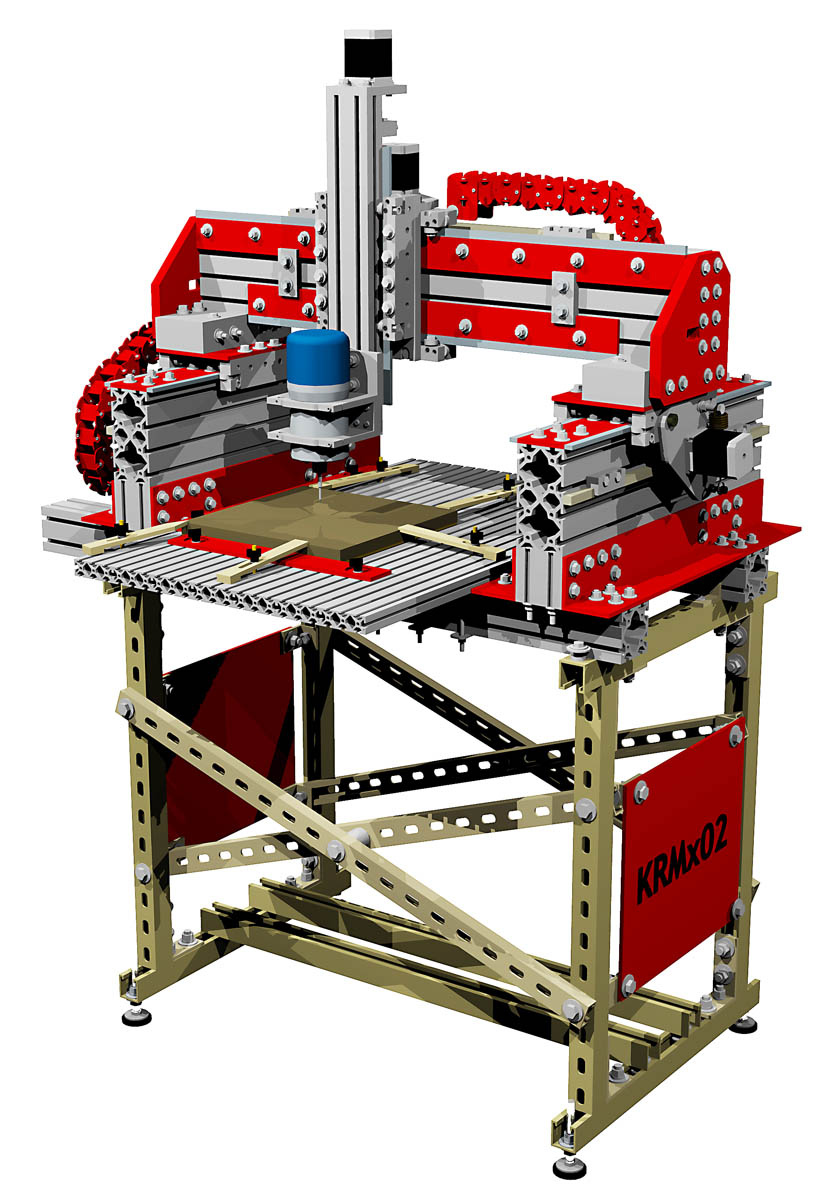

Your design is conservative, but that is what makes this the best build in its class, Rigidity. I've been looking at the KRMx02 and have visited the site to look around. It comes down to the popularity of the machine and the community to help you out. If you are doing a climb cut what does it do when you do a conventional cut? I'm intrigued too if people have feedback. IE always out the same?

| Uploader: | Nikor |

| Date Added: | 13 April 2006 |

| File Size: | 31.4 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 77337 |

| Price: | Free* [*Free Regsitration Required] |

MODERATORS

You can raise the Z-plate up so that you can utilize this clearance with a rotary. In any case, I am very interested in what you come up with.

Kronos estimates the cost of materials on even the smallest one smaller than the Power Route at about the same price of the Power Route and you have to do a ton of drilling, cutting, etc, to get the Kronos together work.

I'm a little unsure if any special tools are needed to cut the extrusions and the steel to length?

Sometimes it can be amazing, other times not. Tags for this Thread axiscadcncengineeringkrmx As for the steel stand, I followed his plan until my wife's uncle offered to weld it for me. Except it's not intrusive, plus, having guys like him and Will Adams Carbide3D on the subreddit really contribute a lot to making this an awesome place to learn from the manufacturers themselves.

My review of building the KRMx This is a guy who has a 8'x24' water jet, some large 3 and 5 axis CNCs watching the tool change on the 5 axis is crazy cooland some huge 4 axis lathes. There is a little over 7" travel.

Kronos Robotics - KRMx02 CNC Workbook Forums

My review of building the KRMx02 As far as special tools go, you will want to invest in a drill press. I have a miter saw, and if you get the Diablo 80t blade for wood and nonferrous metals, you will never have a problem.

Kemx02 you are doing a climb cut what does it do when you do a conventional cut? I'm just very conservative in my specs, as it has to do with how stock you build your table surface and where you mount the Z-plate in the Z-beam.

All available at www. A friend and I spent 2 hours just filing the rough spots.

My review of building the KRMx02

The aluminum extrusion are cut to length and I recommend sourcing a good Steel vender who will also cut it for you. Unfortunately they are private until the sale so you have no idea what you are getting into in this case.

I figured I would be on my own because this clearly his hobby job my going thoughts without experience. Only one correction, The KronosRobotics web site is my full time job.

Your design is conservative, but that is what makes this the best build in its class, Rigidity. Before this, my tool experience was working on a farm fixing tractors and building barns and fences.

One owner is an aviation engineer who is building an experimental aircraft with it and is buildung complimentary of it I even got laughed at once when I asked for "the same prices as last time.

I'd suggest checking with them to see if they have. Furthermore, if Kronos hasn't updated the cost estimates to reflect the recent rise in metals prices then you'd be in for a shock there.

He is dedicated to helping you be successful and full of wisdom and knowledge. IE always out the same? My review of building the KRMx02 How far out is cnx circle? My email is my user name with a gmail account.

One guy even recently posted cutting titanium with the Power Route. News and reviews regarding hobby CNC machines and toolchains Mods and buulding Guides, tutorials, tips, and tricks Show off your projects Share your design files Check out the wiki Related subreddits: But I can't see a need to do this now until I'm ready to add a rotary axis.

I own the company, so I'm biased of course.

No comments:

Post a Comment